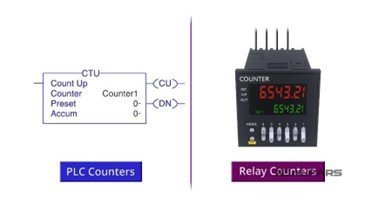

Counters in ladder Logic Programming

Introduction:

Counters in ladder logic programming are used to keep track of the number of occurrences of a specific event or condition. They count up or down based on predefined rules and control the sequence of operations in a control system. Counters are crucial for tasks that involve counting discrete events, managing process sequences, or implementing time-based operations.

Types of Counters

- Up Counter (CTU – Count Up)

- Definition: Increments the count each time an input condition is true.

- Features:

▪ Counts upward from zero.

▪ Can be reset to zero with a reset input.

- Uses:

▪ Counting the number of products passing a checkpoint.

▪ Tracking the number of operations completed.

Example: A packaging line where each product passing a sensor increases the count.

- Down Counter (CTD – Count Down)

- Definition: Decrements the count each time an input condition is true.

- Features:

- Starts from a preset value and counts down to zero.

- Can be reset to the preset value.

- Uses:

- Timing a process or controlling a countdown sequence.

- Managing inventory by counting down the number of items left.

- Example: A production process where a counter decreases each time a product is removed from stock.

- Up/Down Counter (CTUD – Count Up/Down)

- Definition: Allows counting in both directions based on control inputs.

- Features:

- Can count up or down based on control signals.

- Useful for applications requiring flexible counting operations.

- Uses:

- Counting items in and out of a bin.

- Managing complex processes that require bidirectional counting.

- Example: A warehouse system where items can be added or removed from inventory, and the counter adjusts accordingly.

Features

- Preset Value: The target value for the counter to reach, which triggers an action or condition.

- Count Value: The current count of the counter.

- Increment/Decrement: Controls the direction of counting (up or down).

- Reset: Resets the counter to its initial state or a predefined value.

- Overflow: Some counters can handle overflow conditions if they exceed their maximum count.

Uses

- Batch Counting: To manage production batches by counting the number of items processed.

- Timing Control: To measure elapsed time or control processes based on time intervals.

- Sequence Management: To control the sequence of operations in automated systems.

- Inventory Management: To keep track of the number of items in storage or production.

Examples

- Example 1: Up Counter in a Packaging Line

- Scenario: You have a packaging line that needs to count each product as it moves past a sensor.

- Ladder Logic:

- CTU (Counter Up): Increments the count each time the sensor is triggered.

- Preset: Set to a target number of products.

- Output: An indicator light turns on when the count reaches the preset value.

- Example 2: Down Counter in a Production Process

- Scenario: You need to time a process that should last for a specific number of cycles.

- Ladder Logic:

- CTD (Counter Down): Starts from a preset value and decrements each time a process cycle completes.

- Reset: Resets the counter to the initial value at the start of a new cycle.

- Example 3: Up/Down Counter in Inventory Management

- Scenario: Managing a bin where items can be added or removed.

- Ladder Logic:

- CTUD (Up/Down Counter): Counts items added to the bin (increment) or removed from the bin (decrement).

- Control Inputs: Determine whether to count up or down based on the action.

Counters are versatile tools in ladder logic programming that help automate and control processes by accurately tracking events and managing operations based on count values.

Example:

Task 1 for counters (Write a code to turn ON a light after 6 events and turn it OFF after 10 seconds. Events may be treated as two normally open switches.)